Project 2.1 – Materials and Composites for Separation (Jeff McCutcheon)

Background: Currently, H2 is separated from other gases and purified through either pressure swing adsorption or cryogenic distillation, both of which are energy intensive and thus, not cost effective. Membrane separation is currently considered as a promising technology due to its low energy consumption. Various types of membranes from metallic alloys, polymers to novel materials such as graphene oxide, metal organic frameworks have been studied for H2 separation from syngas. Dr. Ostwal research interests lie in the area of membrane separations for gases and liquids.

Objectives: In this project, REU students will learn and explore membrane-based gas separation of H2 from syngas. In Year 1 and 2, REU students will learn how to fabricate polymeric and graphene oxide membranes using established methods. They will then test their membranes for H2 separation performance, using both pure and mixed gas, on an automated gas separation rig. Based on the results, data analysis and understanding of the separation mechanism, the membranes will be optimized towards enhancing their separation properties. This project will allow them to gain hands on experience in fabrication and testing of membranes. In Year 3, REU students will utilize zeolite and carbon molecular sieve membranes to perform the H2 separation test using pure and mixed gases under various conditions of temperature and pressure and explore their separation properties. During this period, they will be tasked with putting together a benchtop gas separation unit to gain hands-on experience in using mechanical tools and building a working system.

Expected Outcomes: By the end of this project, REU students will be trained on using and building gas separation testing units gaining valuable hands-on experience. Incorporating four different types of membranes in the project provides an opportunity for them to understand fundamental separation mechanisms and applying that knowledge to develop better membranes, as well as learn how the test conditions affect the separation performance of the membranes.

Project 2.2 – Hydrogen Contamination Detector (Ugur Pasaogullari)

Background: As H2 becomes a more commonplace fuel, the supply will become diverse and maintaining and ensuring consistent fuel quality will become critical for durability and performance of the H2 utilizing systems, e.g. transportation fuel cells. In collaboration with Skyre, Inc and Los Alamos National Laboratory (LANL), Pasaogullari group have developed a concept for rapidly detecting presence of impurities in the H2 fuel. The concept relies on a miniature electrochemical cell with an applied voltage bias across a pair of electrodes, that can measure H2 pumping current (i.e. redox pair of H2 oxidation and H2 evolution reactions), and the presence of contaminants that affect the performance of the redox pair. The concept has been proven to detect CO.

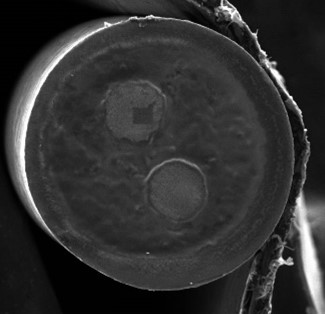

Objective: The overall objective is to demonstrate a multi-electrode array detector, which can detect the presence of multiple impurities simultaneously to evaluate H2 fuel against common standards (e.g. SAE J-2719). In Year 1, the REU student will investigate the operation of multiple individual working electrodes against a single counter electrode within the same electrolyte layer. The individual electrodes will be tuned (materials and operating condition, e.g. bias potential) to detect specific impurities, e.g. a H2 oxidation electrode operating at >0.6V (RHE) will unlikely detect presence of CO due to rapid oxidation at these potentials, but will detect other species such as H2S. REU student will work with the faculty, industry and national lab mentors to develop a computational model for electrode arrays to predict the potential distribution in the electrolyte, and operation of individual electrodes. In Year 2, based on the modeling results, a multi-electrode array will be designed and fabricated. The REU student will be tasked to determine the specific dimensions of the electrode array, select the electrolyte material, determine the pre- and post-processing steps to improve the contact between the electrode and electrolyte layers as well as mass transport to the electrode surfaces. The REU student will then fabricate the multi-electrode array with guidance from faculty, industry and national lab mentors and test. In Year 3, the REU student will work with the industrial mentor to implement the multi-electrode array detector into a H2 refueling station (HRS). With guidance from faculty and the industrial and national lab mentor, the REU student will then develop the auxiliary components (e.g. custom potentiostat, data acquisition and processing) for prototype testing.

Expected Outcomes: The REU students will be trained on modeling of transport and electrochemical kinetics of electrochemical systems, design, fabrication and testing of electrochemical cells and devices, and incorporation of the electrode into larger hydrogen refueling systems. The students will work with mentors from industry, academia and national labs and will be exposed to all stages of research, design and implementation.